PLASTIC WELDING & CUTTING TECHNOLOGY

Welcome to SEDECO USA, INC.

SEDECO USA was founded in November 2005 and is the North American subsidiary of Seidensha Electronics Co., Ltd. Our purpose is to supply Seidensha’s clients’ North American branches and subsidiary companies with localized equipment, support, maintenance, operator training, and all after sales services of our plastic welding technology.

We also aim to introduce new North American clients to the industrial standards, machine quality, and technical know-how that have made Seidensha a trusted name in the plastics industry for over forty years.

Technologies and Product Diversity

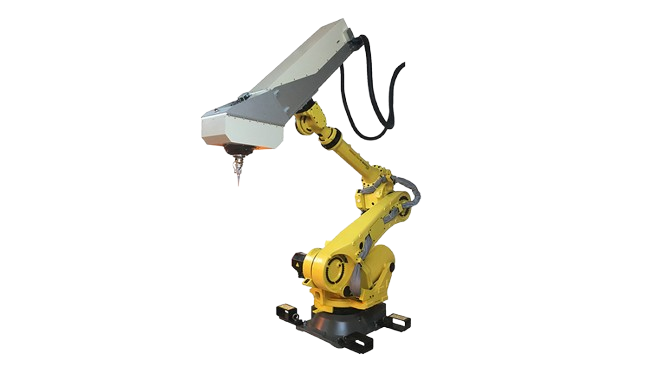

• Ultrasonic Welding / Cutting / Stamping

• Induction Heating (IH)

• Impulse Heating / Welding

• Laser Cutting / Welding

• Radio-Frequency Welders

• Custom Tooling and Jigs

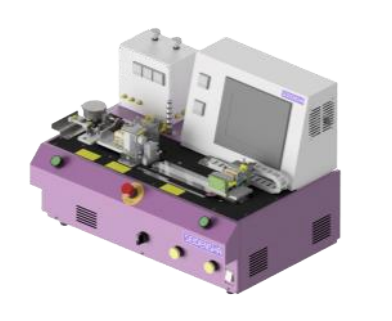

Ultrasonic Solutions

SEDECO deals in all of Seidensha’s plastic assembly technologies, though in North America we specialize in Ultrasonic Welding. We provide Seidensha’s line-up of SONOPET welders and local design / fabrication of custom tool horns and jigs for any-and-all brands of ultrasonic equipment.

FAQs